Exploring the Versatility of Poly Coated Paper in Sustainable Packaging of Dehydrated Food

| 09 May 2024

About Poly Coated Paper:

Discover the benefits of poly coated paper - a versatile and sustainable material offering moisture resistance, durability, and eco-friendly packaging solutions for various industries.

Poly coated paper is a workhorse material, combining the strength and printability of paper with a protective plastic layer. This creates a packaging solution that's both flexible and robust, perfect for safeguarding your dehydrated vegetables.

Imagine a paper that's as tough as your grandma's cookie jar! Poly coated paper achieves just that. A thin layer of polyethylene (plastic) is bonded to paper, giving it exceptional moisture resistance, improved durability, and excellent printability. This makes it a favorite for packaging a variety of products, including – you guessed it – dehydrated vegetables!

Poly coated paper is a versatile material with a paper base and a polyethylene coating, offering durability and moisture resistance for various applications.

Pe coated paper combines the strength and printability of paper with the protective properties of polyethylene. This composite material is created by extruding a thin layer of polyethylene onto a paper substrate, resulting in a sheet that is resistant to moisture, grease, and tearing. Its versatility makes it suitable for a wide range of uses across industries, offering both practicality and environmental benefits when compared to alternatives.

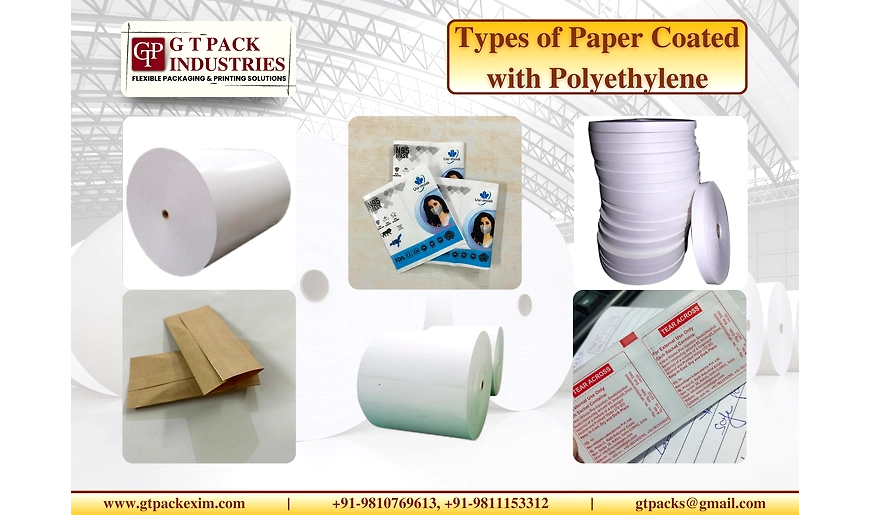

Types of Poly Coated Paper and Its Uses:

Poly coated paper comes in various finishes and can be customized to fit your specific needs. Here's a glimpse into its versatility:

- Glossy Finish: Perfect for eye-catching labels and pouches for dehydrated snacks and seasoning blends.

- Matt Finish: Offers a more subdued look, ideal for bulk packaging of dehydrated vegetables.

- Metallized Finish: Creates a premium feel for dehydrated vegetables destined for gourmet stores.

- Single-Sided Poly Coated Paper: Ideal for food packaging like wrappers and bags.

- Double-Sided Poly Coated Paper: Used in applications requiring enhanced barrier properties such as cups and containers.

Features of Poly Coated Paper:

Poly coated paper isn't just for dehydrated vegetables! It's a popular choice across industries due to its:

- Moisture Resistance: Protects contents from moisture and humidity, ideal for hygroscopic (absorbs moisture) products.

- Durability: Withstands wear and tear, making it suitable for transportation and storage.

- Printability: Creates vibrant and informative packaging to grab attention on store shelves.

Types of Material Used in Poly Coated Paper:

The core of poly coated paper is high-quality paper, often kraft paper for its strength. The plastic layer typically uses polyethylene (PE) for its versatility and excellent barrier properties.

Kraft Paper Coated with Polyethylene:

- Description: Kraft paper, known for its strength and durability, is coated with a layer of polyethylene to enhance its moisture resistance and protective properties.

- Uses:

- Packaging materials for food products, including bags and wrappers.

- Industrial applications requiring tear-resistant and moisture-proof packaging.

Poster Paper Coated with Polyethylene:

- Description: Poster paper, sourced from post-consumer or post-industrial waste, is coated with polyethylene to improve its performance characteristics while retaining eco-friendly attributes.

- Uses:

- Environmentally conscious packaging solutions for various industries.

- Sustainable alternatives for disposable tableware and packaging materials.

Chromo Paper Coated with Polyethylene:

- Description: Chromo Paper rolls are coated with a layer of polyethylene to add moisture resistance and durability while maintaining the stiffness and printability of cardboard.

- Uses:

- Medicines, tablets, Eno Powder Packaging etc

- Packaging boxes and cartons for shipping and storage.

- Display materials requiring a combination of strength and moisture protection.

Paperboard Coated with Polyethylene:

- Description: Paperboard, a thicker and stiffer type of paper, is coated with polyethylene to provide moisture resistance and barrier properties suitable for various packaging needs.

- Uses:

- Food packaging for frozen or refrigerated products.

- Pharmaceutical packaging requiring protection against moisture and contaminants.

Glassine Paper Coated with Polyethylene:

- Description: Glassine paper is a smooth and translucent paper that is resistant to air, water, and grease. Glassine Papers with specific characteristics such as heat-sealable coatings, antimicrobial treatments, or enhanced barrier coatings are coated with polyethylene to meet specialized packaging requirements.

- Uses:

- Heat-sealable packaging for medical products.

- Antimicrobial packaging for sterile environments.

Specialized Papers Coated with Polyethylene:

- Description: Papers with specific characteristics such as heat-sealable coatings, antimicrobial treatments, or enhanced barrier coatings are coated with polyethylene to meet specialized packaging requirements.

- Uses:

- Heat-sealable packaging for food and medical products.

- Antimicrobial packaging for sterile environments.

- High-performance packaging for industrial and commercial applications.

These coated papers serve specific purposes across industries, offering a combination of printability, durability, moisture resistance, and barrier properties tailored to different applications. Polyethylene coatings play a vital role in enhancing these properties for diverse uses in packaging, labeling, and printing.

Types of Industries Using Poly Coated Paper:

Poly coated paper's adaptability makes it a favorite in various industries, including:

- Food & Beverage: Dehydrated vegetables, snacks, spices, and more.

- Pharmaceutical: Blister packs for tablets and capsules.

- Retail: Shopping bags, merchandise pouches, and packaging.

- Agriculture: Seed packets and fertilizer bags.

Types of Material Used in Poly Coated Paper:

The core of poly coated paper is high-quality paper, often kraft paper for its strength. The plastic layer typically uses polyethylene (PE) for its versatility and excellent barrier properties.

Paper substrate (kraft paper, recycled paper etc.) | Polyethylene (LDPE, HDPE) for coating.

Keywords : Poly coated paper for sustainable and moisture-resistant food packaging, versatile material with protective coating, durability and barrier properties for industrial applications, eco-friendly and printing-compatible, grease-resistant and cost-effective solution, recyclable and customizable for various consumer goods, including disposable tableware, labels, stickers, and logistics packaging, offering environmental benefits across industries, Poly coated paper, moisture resistance, food packaging, versatile material, sustainable packaging, protective coating, durability, barrier properties, eco-friendly, industrial applications, printing compatibility, grease resistance, cost-effective, recyclable, customizable, consumer goods, disposable tableware, labels and stickers, logistics, shipping, environmental benefits, Poly coated paper manufacturer in india, Poly coated paper Supplier, coated paper manufacturer, per coated paper manufcaturer, pe coated paper, pe coated kraft paper, pe coated paper suppliers, poly coated kraft paper manufacturers, chromo paper manufacturers, pe coated paper price, pe lamination paper,