Unit Price of Flexible Packaging Material

| 10 Feb 2025

Optimizing Unit Price of Flexible Packaging Material

let's Maximize the Value in Every Flexible Packaging Pouches

In today's Competitive business era, especially for manufacturer that rely heavily on Flexible Packaging Material, Understanding and optimizing unit price isn't just a cost saving tactics. Knowing costing of a Packaging material user is a strategic advantage for saving cost and increased profits. At G T Pack Industries, we believe that achieving the best value from every packaging investment starts with a deep understanding of Unit Price Dynamics.

What is unit price in Flexible Packaging?

Unite Price refers to the cost of a single unit of Packaging Material. This metric is more than just a figure on an invoice. It reflects how efficiently and effectively your packaging strategy aligns with your business goals, optimizing unit price isn't about finding low cost options. It's about maximizing value through cost efficiency, quality, and strategic purchasing decisions.

The Power of Economies of scale: Why buying Packaging Material in Bulk Quantity Matters?

One of the most effective strategies to lower your unit price in purchasing packaging material or pouches in bulk. this taps into the principle of economies of scale, where the cost per unit decreases as the quantity increases.

benefits of Bulk Purchasing of Flexible Packaging Rolls or Packaging pouches:

- Cost Efficiency : Bulk quantity orders often comes with significant discount, reduced wastage, freight cost benefit and significant reduction of the overall cost per unit.

- Consistent Quality : Bulk Quantity Order are typically produced in a single batch, ensuring uniformity and consistency across all units.

- Reduced Administrative Burden : Fewer Transactions mean less paper work, simplified logistics, and lower administrative costs.

- Reduced Wastage : Specially in Flexible packaging industry having rotogravure printing technology, their is initial wastage which is around 3% where as, overall wastage in all segments are being combined with 5% only.

- Inventory Stability : Having a steady supply reduces the risk of stock-outs during peak demand periods.

Breaking Down the Unit Price: What Factor Matter?

To optimize unit Price Effectively, businesses need to understand the components that influence it:

- Material Costs : The type of substrate (Poly Coated Paper, Aluminium Foil Laminates, Fabric Based Products, Packaging Pouches, Printed Flexible Packaging Material etc.) directly affects pricing.

- Printing and lamination : Advanced technologies like 8-color and 6-color rotogravure printing can enhance design without significantly increasing costs.

- Customization Level : Specialized pouch types (stand up pouches, gusset pouches, center seal pouch, side seal pouch etc.) may carry additional costs.

- Logistics and handling : Bulk Shipment can reduce per unit shipping costs.

- Sustainability Options : Eco friendly materials may have upfront costs but offer long term value through brand reputation and regulatory compliance.

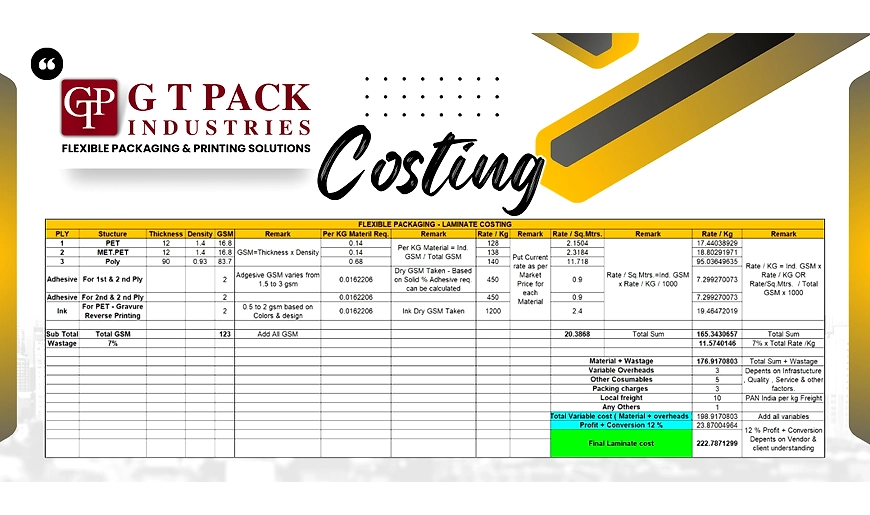

Case Study: Comparing Bulk and Retail Quantity Orders

Scenario 1: Retail Quantity Purchase (300 kgs)

A Business purchases 300 kgs of Flexible Packaging With the following structure:

- PET (Polyester) - 12 microns

- MET PET (Metalize Polyester) - 12 microns

- Poly (Multilayer Polyfilms) - 35 microns

Cost Breakdown:

- Material Cost : Rs. 235 Per Kg

- Pouching Cost : Rs. 20 Per kg

- Logistics and Other Costs : Rs. 7 per kg

- Fixed Wastage : 3% of 300kgs material

- Finished Wastage : 3-5% on finished goods (Pouching Process)

Key Insights:

- Higher Wastage Impact : The fixed wastage and finishing losses significantly affect the effective cost per kg.

- increased unit price : Due to higher wastage and smaller scale, the unit price is comparatively higher.

Scenario 2 : Bulk Quantity Purchases

When Purchasing in bulk, the business experiences:

- Reduced Wastage : only 9 kgs of wastage is there as bulk quantity is more than 300 kgs and due to this significant reduction in cost of wastage.

- Lower Logistics Costs : Economies of scale reduce transportation costs.

- Optimized Production : Fewer Changeovers in the production process lead to less material loss.

Result :

- Lower Unit Price : Due to reduced wastage, efficient pouching, and minimized logistic expenses.

- Consistent Quality : Bulk Orders Maintain Uniform Quality across large batches.

Balancing Quantity with Quality

while bulk purchasing reduces costs, it's essential to maintain a balance. A Low Unit Price Shouldn't Come at the expense of quality. At G T Pack industries, Our advanced extrusion coating and solvent based lamination technologies ensure that every package meets the highest standards regardless of order size.

Pro Tips for Optimizing Unit Price :

- Forecast Demand accurately : Avoid Over ordering, Which can lead to storage issues or material wastage.

- Negotiate Long term Contracts : Locking in rates for extended periods can protect against price fluctuations.

- Standardize Packaging Where Possible : Reducing Variation across products can lead to production efficiencies.

- Consider Sustainable Solutions : Eco friendly Packaging pouch might have higher upfront costs but can reduce waste related expenses.

Achieve More Value with G T Pack Industries

At G T pack Industries, we don't just supply flexible packaging materials or packaging pouches, we help businesses optimize their entire packaging strategy. whether you're looking to reduce costs, improve quality, or enhance sustainability. Our team is here to guide you every step of the way.

Ready to optimize your packaging material per unit price and maximize value?

Contact G T Pack Industries today for a FREE Cost analysis and discover how we can help you achieve more with every package.

Keyword - Unit Price in Flexible Packaging, bulk Packaging cost, bulk Packaging cost benefits, flexible Packaging Materials, economies of scale in packaging, packaging cost, stand up pouch cost, price of packaging pouch, how to reduce packaging costs, Flexible packaging pouch price, Unit Price Optimization, Bulk packaging pouch, packaging cost efficiency, G T Pack Industries, Cost effective Packaging Solutions